Beta invests US$5m in Mt Hampden plant

Brick manufacturer, Beta Holdings, says it has invested US$5 million in a new production plant, as the company moves to take advantage of the growing demand for bricks on the domestic markt.

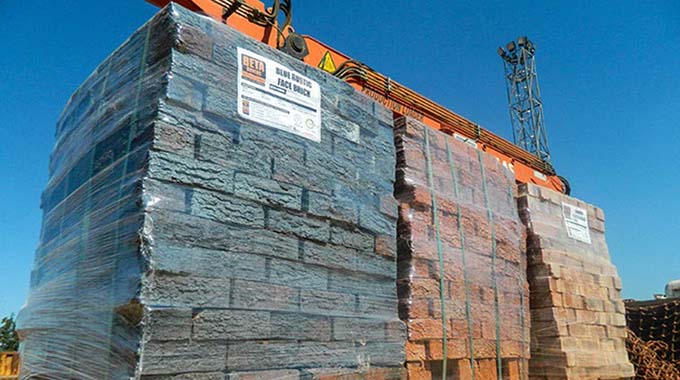

The new plant, which is already operational, has added about 50 million bricks per year to the firm’s existing Mount Hampden plant throughput from to the previous annual capacity of 125 million. According to Beta Holdings, the newly installed machinery currently specializes in production of face bricks and common bricks given the company’s demand gap.

Lately, demand for bricks has increased on account of growing individual home constructions and Government projects around the country, a development that has seen brick makers struggle to satisfy the domestic market demand. Speaking during a tour of Beta Holding Msasa and Mt Hampden plants, factory manager Nativity Mabasa highlighted that the demand for bricks was expected to surge in the short to medium term, but the company had moved to meet the looming demand at hand.

He said before the new plant was completed, the company was operating Steele 50 and Steele 75 plants producing nearly 130 million bricks per year in Mt Hampden.

“We had two machines in the past doing 68 million bricks and the other plant was doing 57 million bricks per year, so this year we commissioned a factory to add on to our products so we have added another 50 million capacity.

“Our demand is at peak given that the Government is embarking on many construction projects, the demand is growing despite the improving number of brick companies in the country,” said Mr Mabasa.

Beta Holdings’ Mt Hampden plant produces the highly sought-after clay bricks while the Msasa plant makes concrete bricks and pavers.

Mr Mabasa bemoaned the company’s dependency on natural weather to dry bricks, a process he said was reducing output, especially during the rainy season.

This means the manufacturing process takes too long, a situation the company intends to address by investing in drying machines (starting with the Melfort plant) to speed up the brickmaking process.

“We depend on good weather to dry our bricks when it is raining we stagger our production, which is our biggest disadvantage, especially in summer,this makes our production very slow during rainy season,so instead of producing 4 million bricks per week , rain season production is reduced to as low as 2 million bricks per week.

“There are however emerging technologies like dryers now, the dryers take about 48 hours to dry the bricks instead of the 21 days we are taking at the moment,” he added.

Beta Holdings is the flagship of the Beta Group being the largest subsidiary both by production and market share it offers a range of bricks ranging from the popular common brick and over 21 different types of face bricks.

Going forward, Beta bricks intends to increase capacity by about 90 million bricks per year at its Melfort plant, which is set to be commissioned in the fourth quarter of 2022 and construct a new plant in the border city of Mutare by August this year with capacity of 15 million bricks.-The Herald