Zisco gets partners to carry out feasibility studies

REDCLIFF-based steel manufacturing company, Ziscosteel is carrying out feasibility studies with a German firm and other local companies to explore the latest production technology to ensure the steel maker is carbon emission compliant as it intensifies its resuscitation drive.

Ziscosteel is on a phased resuscitation drive that will largely hinge on replacing obsolete equipment with modern machinery as the company seeks to find a long-lasting solution as well as reduce carbon emissions.

The government gave Kuvimba Mining House the mandate to spearhead the resuscitation of the company which had been idle for the past decade and it’s systems go on the ground with a lot of feasibility studies being conducted.

Zisco board chair Engineer Martin Manuhwa said they seek to utilise green steel which is environmentally friendly as they reduce carbon dioxide emissions.

“We want to work with green steel and carbon steel because what we want to do is to use less carbon and emit less carbon dioxide into the atmosphere. So, there are better fuels like hydrogen and even more efficient ways of smelting blast furnaces technologies that we are going to use,” said Eng Manuhwa.

The whole integrated system will be worked out such that carbon footprint is reduced as the company escalates its fight against climate change, he added.

“We have to be people centred and climate and planet conscious so that we do not pollute the environment.

“Our aim is to ensure that we meet the international benchmarks in terms of carbon emissions, so we want to move with modern technology,” he said.

Feasibility studies were already underway in that regard.

“We are currently carrying out feasibility studies with a Germany company and other local companies so that we can get abreast with the latest technology and then we will be able to resuscitate the steel plant especially, using modern steel,” he said.

Notable progress has been recorded since Kuvimba went on the ground with the company having received US$2 million for the limestone mining which is expected to start at the end of this month.

Another US$30 million will be channelled towards the resuscitation of the iron and steel mining as well as resuscitation of the steel plant.

“Limestone mining should be able to commence by the end of August if all goes well and it will start with a target of 20 tons per month before increasing to 80 tons per month. It’s a complex process and we are doing everything wisely and putting every system in place for that,” said Eng Manuhwa.

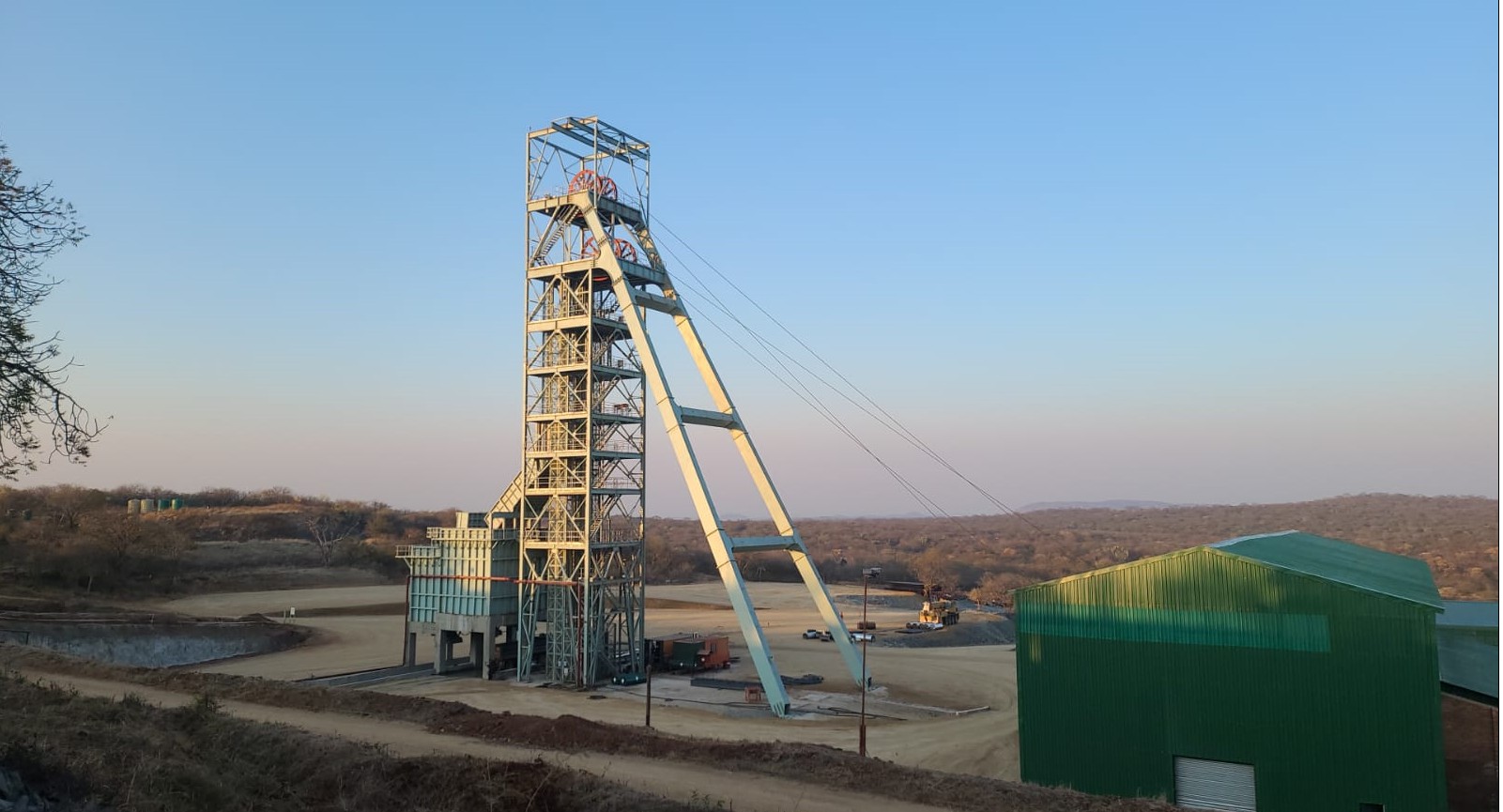

Resuscitation of Ripple Creek and Buchwa mining are at advanced stages with the removal of obsolete infrastructure which is being replaced by modern equipment and funding has since been availed for that.

Famed for reviving mothballed companies, including Jena Gold Mine, Shamva Gold Mine among others, Kuvimba is expected to play a key role in the resuscitation of the giant steel company, which used to employ 5 000 workers at its peak.

Its closure in 2008 came at a cost to the country’s economy and foreign currency prospects amid reports of the country using US$1 billion for the import of steel.

The company, which employed more than 5 000 workers at its peak, is expected to build its employment base from its former and current employees.

In 2018, the Government took over the giant steel company’s $495 million debt to pave the way for its resuscitation which also included salaries and pensions.-chronicle