Two new plants to help Beta Bricks meet demand

BETA Holdings, one of the country’s largest suppliers of building materials, is set to commission two brick-making lines in the next three months in a development expected to bridge the current supply gap in the market, an official has said.

While Zimbabwe has traditionally struggled to meet the demand for bricks due to capacity constraints, the shortages worsened in recent years largely due to strong demand from private and public sectors as well as home developments by diaspora funds. Even with the coming of various players into the brick-making sector, the industry’s aggregate output still remains below the levels required to meet the national demand.

The coming in of the new lines, in Mt Hampden and another one in Melfort, about 50 kilometers east of Harare, would see the company doubling brick output and ease the current supply constraints, BETA chief executive Mr Godfrey Manhambara said.

The Melfort plant, which is behind its original commissioning timelines following the late delivery of the equipment due to Covid-19-related shipping challenges, is expected to start production in August.

It is expected to churn out about 18 million bricks per month. The Mt Hampden line, situated where the company is currently producing from, is expected to start “soft” plant commissioning this month in preparation for full commercial production, Mr Manhambara said.

The plant is expected to produce between 1,2 and 1,5 million bricks per week or up to 6 million per month.

“We hope the new capacity we are putting in will help solve the current supply constraints that have seen people placed on waiting periods after paying,” said Mr Manhambara.

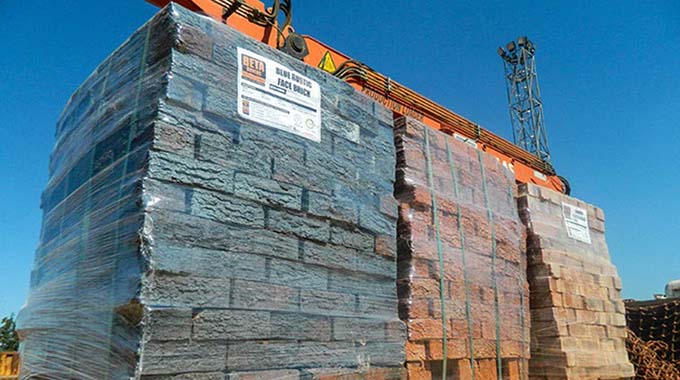

Civil works and some of the equipment for Beta Bricks’ Melfort new brick-making line

“For us, that is not business; that is why we have taken a position of adding capacity.

“The capacity has been largely stagnant and the inevitable happens (the shortage). There is no other solution than to increase the capacity,” added Mr Manhambara.

The Herald Finance & Business recently visited the site where the Melfort plant is being built. Civil and engineering works are at an advanced stage.

Most of the US-made equipment is at the site and installation is expected to commence early next month.

The power line to the plant has already been installed.

“When we did the groundbreaking ceremony, it was during the height of Covid-19. Apart from shipping challenges, we earlier had challenges in accessing foreign currency from the auction system. Then obviously, the lead time (the period between the placement of an order, manufacturing,

and delivery) but we are happy everything is now on course.”

The expansion of the Melfort plant, which will be the company’s flagship operation, will come later on and will involve adding drying tunnels. This will eliminate production stoppages due to the rains. Brick producers normally halt production in rainy seasons as the wet conditions are not favourable to operations.

“We call it an all-weather plant. There will be no shutdowns because of the rains,” said Mr Manhambara.

Apart from the brick division and the aggregates plant, BETA also incorporates BETA Concrete. BETA Bricks is the first brick manufacturer in Zimbabwe to receive international certification for integrated ISO management systems. The company offers a range of clay bricks ranging from the popular common brick and over 21 different types of face brick.-herald