Bulawayo companies’ mechanisation, automation impresses Government

THE Ministry of Industry and Commerce has commended the mechanisation and automation of Bulawayo companies, which has increased their capacity utilisation and productivity, critical to the city’s re-industrialisation drive.

The Second Republic has made significant strides in the re-industrialisation of Bulawayo, attracting investments and creating employment opportunities.

This resurgence is a testament to the Government’s commitment to fostering economic growth and prosperity in the region.

The city is experiencing a renaissance, with investor interest surging and re-industrialisation efforts taking root. Bulawayo, which at its peak boasted large industries, has witnessed re-industrialisation efforts, which are in line with the country’s Vision, which aims to transform Zimbabwe into an upper-middle-income society by 2030.

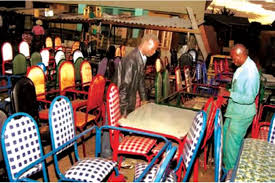

The Minister of Industry and Commerce, Mangaliso Ndlovu, together with ministry officials, on Thursday toured the modern Satellite Leather Design Studio housed at the Leather Institute of Zimbabwe, Role Retail Solutions (formerly Arenel), and Ingwebu Breweries.

INDUSTRY and Commerce Minister Mangaliso Ndlovu

On Friday, the Ministry of Industry and Commerce permanent secretary, Dr Thomas Utete Wushe, visited National Foods Limited. These companies have invested millions of dollars in state-of-the-art mechanised and automated plants as part of their expansion and diversification initiatives.

In an interview after the tour, Dr Wushe said: “As a Ministry, we realised we need to engage with Bulawayo industries, as the city is working towards regaining its former status as the country’s industrial hub. We have seen the new plant at National Foods where investment worth about US$6,5 million has been made. Local companies are embracing automation in their operations, which is in line with the Fourth Industrial Revolution. This is critical as it enhances efficiencies and minimises manual work-related injuries.”

He said automation had an impact on upskilling and this is where the Ministry of Higher and Tertiary Education, Innovation, Science and Technology Development also comes in as many companies are adopting modern equipment.

Dr Wushe said there was also a need to address the capacity utilisation of local companies.

“The Minister met Bulawayo industrialists at the ‘Doing Business in Matabeleland’ breakfast meeting and it was revealed that the city’s capacity utilisation is at 45 percent, which means there is room for improvement. We will work with industrialists to ensure that we increase capacity utilisation,” he said.

Dr Wushe said the launch of the Zimbabwe Industrial Reconstruction and Growth Plan (ZIRGP) represented a forward-thinking and comprehensive approach to addressing the country’s industrial challenges while fostering long-term economic growth.

Ingwebu Breweries’ managing director, Mr Dumisani Mhlanga, said they had expanded their workforce by 21 employees following the installation of a state-of-the-art US$1,7 million PET (Polyethylene Terephthalate) beer packaging plant.

The investment is part of the company’s broader strategy to enhance product distribution, extend shelf life and strengthen its competitiveness in the rapidly evolving beverage industry.

Role Retail Solutions’ compliance officer, Mr Stephen Ncube, said last year, the diversified manufacturing powerhouse made a significant leap forward by installing new production lines for biscuits and pasta, a project valued at US$2,5 million.

He, however, said the upgraded production lines remained idle because Zesa was insisting that the company should buy its own power supply equipment.

“It has been a year now since we installed a new biscuit production line. The primary obstacle is the requirement by the Zimbabwe Electricity Distribution Company (ZETDC) to purchase our own power supply equipment.

The estimated cost of the equipment is US$150 000,” he said.

Mr Ncube said the company had in the past been asked to buy the power supply equipment, which after being installed became the ZETDC property.

“We requested that the investment be considered under the Customer Supplied Material Scheme whereby ZETDC reimburses us in units but this has not yet been done,” he said.

Mr Ncube said the company asked ZETDC to either supply and install all the necessary power supply equipment to provide the additional electricity required for their new biscuit production line, or to commit to the Customer Supplied Material Scheme and reimburse them in energy units.

He said such an arrangement would not only benefit the company but also align with the Government’s aim of modernisation and energy efficiency.-chrocnile